Understanding Your Wheels & Nuts Compound & Finish

Not many cars sold or on the road today come with the classic steel wheels and plastic hub caps. Modern manufacturing processes have taken the alloy wheel from the options list onto the standard kit over the last decade, however these alloys and designs are again evolving. Understanding what’s in the market is essential for both the cleaning process and products required for the longevity of healthy wheels and hubs

The definition of an Alloy is “a metal made by combining two or more metallic elements, especially to give greater strength or resistance to corrosion”. Usually Aluminium forms the base of a possible combination with Magnesium, Titanium, Nickel, Copper, Iron or Manganese. Then you’ll have the combination of the metals at different levels to achieve different effects adding to the complexity.

The video shows the manufacturing process of making the wheels and gives you everything you need to be seen as the wheel expert at the pub.

Once the wheels are formed they are often treated before they reach the customer with most basic alloys lacquered before being sold. Very few are sold without some protection over the metal before they hit the road.

Lately the choice of more exotic finishes available from the OEM’s as well as the aftermarket to add design and colour can be vast. Wheels can be polished, polished and lacquered, painted, painted and lacquered, powder coated and anodised (a controlled reaction to create a layer of oxide which is more chemically resistant than the underlying metal). Some two tones have two of these treatments on. Some two tones are treated in parts and polished in other parts then lacquered over the top. The variables are enormous and often the owner doesn’t know what the actual finish is or how it has been achieved, more importantly how to look after it.

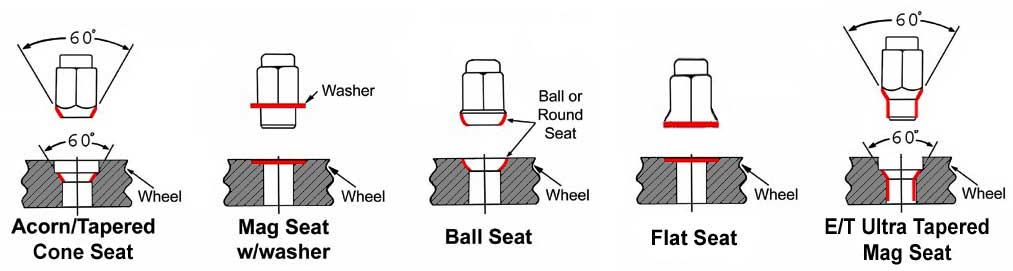

Part of purchasing new aftermarket wheels is the choice of aftermarket wheel nuts to compliment the look you are after.

Wheels go through a lot of abuse from weight, curb scratches and knocks, road bumps and the increased G-forces applied during racing. They have to be robust enough to withstand a multitude of lateral and vertical impacts.

Wheels nuts often don’t have the same qualities as the wheel and are often purchased on price or looks. When purchasing any new wheel nut, consider the material they are made from. Does this match the material and quality you need to withstand the pressures you are putting on the wheels and your driving habits of the car? Some wheels are very robust while the nuts are a much softer metal than the wheel.

If you remove your wheels often for track work, burnouts or shows, the wheel nuts come under a lot of contact abuse from rattle guns or simple wheel wrenches. This increased metal to metal contact means premature wear that can remove the protective coating applied to the nuts, exposing the base metal to environmental factors and the cleaning chemicals applied to the car and wheels, creating premature oxidation.

Finally, having softer wheel nut metals will mean that choosing the correct wheel cleaner is essential. Don’t just think about your wheels when liberally squirting Brand X cleaner over the wheel, you need to think about all aspects. Corrosive cleaners, applying incorrectly, leaving on too long and not rinsing fully can leave the nuts to corrode over time, often giving way at the wrong time.

When buying a car or a new set of aftermarket wheels or nuts do a little research or ask the manufacturer what the alloy is made from and what the finish is. Knowing this will help select the correct wheel cleaner and keep the look you purchased for a lot longer.

What contaminants are found on dirty wheels?

In order to create a safe and reliable wheel cleaner, understanding the wheels compound limitations, the contaminants and how they bond to the wheel is essential in treating any wheel.

So what forms that layer of dirt on your wheel? It’s a combination of rubber deposits, soot, exhaust deposits, soil (varies with area), salt, and air pollution. These contaminants all form part of the external ‘dirt’ bonding and layering on your clean wheels. Then in addition to that there will be a high concentration of brake dust which matches the composition of the pads and the disk. Usually the little black dots which are hardest to shift are iron deposits and the quantity and qualities are closely linked to the type of car/braking system.

The final contaminant is often Tar which is one of the stickiest and hardest to safely remove without damaging your wheel finish.

For those that track their car or enjoy “spirited driving” we know how much dirtier the wheels become after a day on the track over normal driving. This is due to a few reasons.

The biggest factor here is the heat generated within the wheel and braking system. Hot ‘things’ have a lot of energy to react with anything they come into contact with, forming stable bonds which makes them stick like glue. Things which are mobile when they’re hot become very hard to shift when they’ve cooled down as the bond to the surface.

High Impact Speed also comes in play when looking at dirt. When we talk about high impact speed it’s about how fast the wheel rotates to impact on the particle as it comes off the brake – just look at the leading edge of a wheel spoke versus the trailing edge. The further away from the hub usually sees more stubborn dirt built up as the rotation of the wheel is faster.

One of the main contaminants of stubborn wheel soiling is the iron particles. Hard braking creates the high heat and wear which in turn increases the hot iron particles coming off the braking components from both the pads and disk. These iron particles literally “melt” into the lacquer that’s protecting the wheel and stick to it. When the particle cools its stuck in the clear lacquer.

Some cars and manufacturers do suffer from brake dust more than others even during normal driving, especially the Euro’s. This is really down to the composition of the pads and disks, all designed to perform as the manufacturers intended. Even though they create a lot of dust, they often brake hard. Managing this dust can be achieved however, which we will tackle in Part-4.

Next section sees us tackle the two different style of wheels, the traditional OEM Alloy and a newer two tone painted alloy. Totally different wheels with a totally different approach.